- Brand

- FLUIMAC

- Product Name

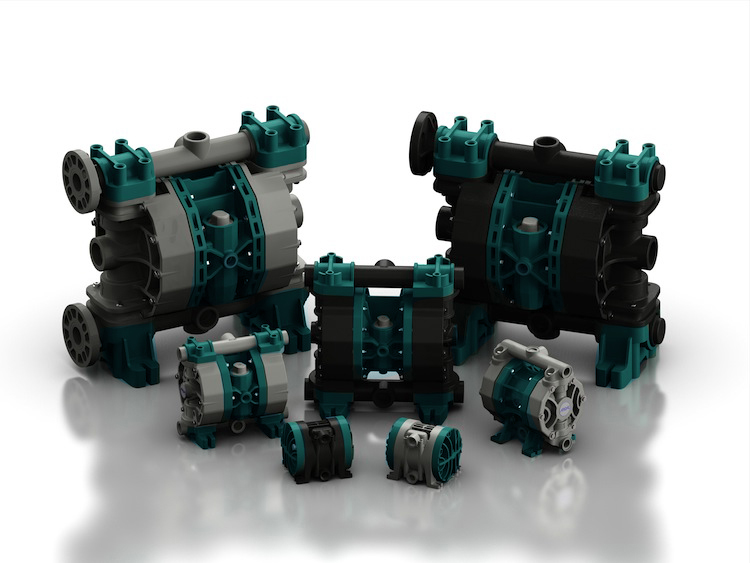

- Air Operated Double Diaphragm Pumps

- Item

- ASTRA

- Link

- Go

- Brief Introduction:

- Chemistry, Painting, Spraying, High viscosity Fluid

-

Thanks to its multiple and simple installations, the pumps are convenient for every operation, from transfer to supply, circulation, injection, evacuation or liquid dosing.

1. Safe: Operated by compressed air and are intrinsically safe.

2. Able to run dry.

3. Self-priming: Allows high suction lift even at dry start and with heavier fluids.

4. Shear sensitive: Gentle pneumatic movement makes it an excellent choice for shear sensitive fluids.

5. Portable & simple installation: Simply connect your air supply line and liquid lines and the pump is ready to perform. No complex control for installing and operating.

6. Submersible: Can run submerged in the liquid by simply running the exhaust line above the liquid level if external material are compatible.

7. Variable flow rate & discharge pressure: Offers the ability to vary flow and discharge pressure up to 120 psi with a simple adjustment of the air supply.

8. Handles a wide variety of fluids with high solids content: No close fitting or rotating parts so liquids with high solids content can be easily pumped (Any liquids with max of 90% solids).

9. Dead-head: Because the discharge pressure can never exceed air inlet pressure, the discharge line can be closed with no damage or wear. The pump will simply slow down and stop. -

AODD pumps are obtained using the best thermoplastic polymers of our territory (Italy). Realized with injected polymers reinforced with composite fiber, AOOD pumps guarantee an optimal mechanical seal as well as a notable corrosive resistance.

Solutions are in fiberglass polypropylene (PP + G) and in polyvinylidene fluoride reinforced with carbon fiber (PVDF + C) and are also available in ATEX ZONE 1 applications version, for strict and dangerous areas.

The metallic variations can be distinguished for their reliability and low-costs versions in aluminum and AISI 316 of the ASTRA range.

Whereas the AISI 316L and exotic alloys (bronze, duplex) versions of the MISTRAL range are focused on robustness and chemical resistance. -

ASTRA range is ideal for the most various industrial applications.

This newest project is made with the very last technologies to guarantee a major reliability of the pump: lifetime and diaphragms are improved, maintenance operations are reduced and it has an enviable quality/price offer.

ASTRA COMPACT range is composed of smaller sizes made for OEM customers, guaranteeing the major constructive simplicity and taking up the minimal amount of space.